To most of the Internet, Mr. Money Mustache is known as the quirky early retirement financial guy, and this is a blog about Money.

But really, I’m not a finance guy – someone who devotes most of his time to optimizing money. I’m more of a general Life Engineer – someone who tries to optimize everything that is fun and interesting in life, and money is just one of those things.

Optimizing means getting the most good out of something – whether it is money, time, health or happiness, while minimizing waste. This is what allows us to make win/win decisions (for example things that make you richer and healthier and happier), rather than win/lose compromises (giving up something you actually like, just to save or earn more money)

One of these win/win things for me has always been optimizing my own houses and buildings to be more comfortable and stylish, while costing less to own and maintain and heat and cool. After all, out of all possible decisions, your choice of home may have the biggest effect on both your financial and emotional wellbeing. Get a reasonable house that is close to your friends and your work, and you’re off to a great start.

So anyway, this past summer all my favorite factors of optimizing, learning, effort, saving shit-tons of money and reducing loads of waste and pollution came together in the form of a DIY Heat Pump Installation on our commercial building downtown, the home of .

Why Are Heat Pumps Super Exciting?

Heat pumps are a technology that has recently jumped into prime time and are about to change everything about houses, just as the iPhone did to the tech industry about twelve years ago and just like electric cars are doing to transportation right now. The reason is that they have these fundamental advantages:

- Heat pumps do the double-duty of heating and cooling any building way better than our existing systems do, but with only one machine.

- They are super easy to install, and way cheaper to run. They also allow houses and buildings to be constructed more cheaply (less materials and labor).

- They eliminate a big part of the world’s pollution that is caused by burning oil or gas for heat (as long as you get your electricity from clean sources).

- And yes, nowadays they work in virtually all climates (down to -20F / -29C): tech improvements have shattered the old limitation where they only worked in places without a real winter.

How Does a Heat Pump Magically Suck Heat Out of Cold Air?

Heat pumps save money and energy because they aren’t generating heat directly like an old electric baseboard heater. They are mostly just moving heat around – from inside to outside in the summer, and from outside to inside in winter.

To many people, that second situation sounds like magic, but that’s just because of our skewed perception as human beings – a creature that evolved in the warm tropics of the planet Earth. Really, there is plenty of heat even in winter air – if you view it through the Eyes of Physics:

So, a modern heat pump can easily suck loads of heat even out of air that feels cold to your skin. It does it like this:

You know what else does this exact same trick? Your own FREEZER! Those things typically maintain an inside temperature of about -10F, which means that somehow it is sucking heat out of the air even at sub-zero temperatures, pumping it out to the coils underneath with a fan blowing past them. And if you put your hand there to feel that airflow, what do you feel? Warmth!

Show Me The Money

Before we get into the real details, check out the quick numbers for the heat pump I just installed. Note that I live in Colorado, which has lots of heat and a – right about what you’d expect from our position halfway between Maine and California.

- Cost of the system including all install materials: About $4500

- My building’s previous annual gas bill: $951

- Our new annual electric bill for heating and cooling (estimated): $275

- Annual savings: $676

Annual return on investment (ROI) rate: 15%

.

Even better: That $275 annual figure for our electricity consumption is what we would have paid, if we had to buy all our electricity off the grid at 10 cents per kWh. But since we generate a surplus of power from our , our net cost is much less than that.

You could even say that all of our heating and cooling is “free” on an ongoing basis, although we did spend $5000 to build the 5.5 kW solar setup in the first place.

So Is A Heat Pump Really a Do-It-Yourself Project?

In a word: Yes, if you are a fairly competent do-it-yourselfer, and you choose a DIY-friendly heat pump kit. It is considerably easier than or a , but not as easy as putting together IKEA furniture.

Our first install took about 16 person-hours of work for the main job (two people working a full day). Plus I spent about another sixteen dusty hours upgrading the duct work and building custom metal shapes to route the air because our coworking building was so old that the original asbestos-and-mouse-shit ducts were just not worth keeping.

The value of doing it yourself is that furnace work is one of the biggest returns on your time as a homeowner. Where I live, even a gas furnace + air conditioner replacement can cost $10,000. And although a heat pump hardware only costs about the same amount as conventional furnace+AC ($4000), the companies like to charge more for the newer stuff (or even worse, try to convince you that you’re stupid for even asking about it!).

In other words, even conservatively speaking, for a basic installation you are saving about $6000 in exchange for doing that 16 hours of work, which amounts to a solid $375 per hour.

Even if you’re not a tinkerer, there are some good programs out there that will help subsidize the cost of an upgrade like this. The US EPA offers for lots of things including heat pumps, and local agencies have their own programs – for example neighboring Fort Collins will towards a unit like ours, which could cover most of the cost of a professional installation.

.

So if you are ready to upgrade to a heat pump, you either need an honest HVAC company who will install a reasonably-priced machine for you and charge you a reasonable hourly rate. Or, you need to flex your Money Mustache Muscles on the project and do it yourself.

Of course, I chose the latter approach as always, so let’s get into the details of or install!

Step One: Pick a Heat Pump

There are two things you’re looking for here: physical size and heat output.

The size and shape of indoor portion (the air handler) of the new system have to be similar to your old furnace, or you need to have a plan for how to adapt the new one to blow into your old pipes. As you’ll see below, I chose to do the adapting.

As for the heat output, old furnace was a “100,000 BTU” unit, which is a measure of the amount of natural gas it can suck in and burn each hour. Since it was only about 75% efficient, the heat output was about 75,000 BTU (the real units here are the archaic “British Thermal Units Per Hour”, but all you really need to know is that this is still more than enough to keep our leaky, sprawling 2400 square foot brick building warm easily through even the coldest winters.)

In the most extreme situation (for us this would be a 24-hour period where the temperature is barely above 0F, and it typically does happen at least once every few years), I measured that our old furnace was running for about 8 hours per day, which means our average heat loss was about 25,000 BTU on a continuous basis (75k multiplied by ⅓ of the total hours in a day)

On the cooling side, we had virtually no air conditioning. Just a few crappy portable units scattered throughout the building, with a total combined cooling power of about 20,000 BTU. This wasn’t quite enough to beat the heat in the event of a fully occupied building on a 100F day.

The solution for me was thus pretty simple: the biggest Mr. Cool “Universal” combined heat/cool system, which I started conveniently seeing Google ads for everywhere once I started my research. This beauty is good for about 60,000 BTU of both heating and cooling, which could also be expressed in the even more archaic form of “5 tons”

So I bought the circled option above. In my case, I placed the order through Home Depot website, with the free “ship to store” option, but you could also try your local Lowe’s, Alpine Home Air is good, and Ingrams now

Step Two: Remove your old furnace

Safety tip: Make sure you turn off both the gas and electric supply to your furnace before messing with it, as well as opening some windows and running a fan to clear out any remnants of gas as you disconnect pipes.

But once you have it safely disabled, it is as simple as carefully un-wrenching, unscrewing, and cutting away parts of the old furnace (while carefully preserving your existing ductwork) until you have the old one fully removed. You can sell or give it away on Craigslist, or drop off for free at a metal recycling facility.

Step Two: adapt the ductwork as needed

If you’re lucky (the old furnace and new heat pump are almost the same size), this step will be easy. You just connect the return ductwork to the bottom of the machine, and the supply ducts to the top. However, I was not lucky.

Because our basement ceiling is so low, I had to install the heat pump horizontally (it is designed to allow this), and then build some adapters to allow the air to flow the way I needed. On top of that, most of our ducts were falling apart and poorly shaped and useless – so I repaired or replaced a bunch of them while I was in the process. This took a lot of work, but my biggest allies were a huge roll of wide, reinforced silver tape, and simple sheet metal tools like shears, angle grinder, self-piercing screws, a good breathing mask, headlamp and work gloves.

Step Three: Fit in the new heat pump

Aside from the fact that the thing is heavy (ours was around 250 pounds), this connection is surprisingly easy once you have the ducts ready. You just screw and seal the sheet metal boxes to the bottom and the top of the heat pump. And at this point, you should be getting excited because the end is in sight.

Step Four: Place the Outdoor Unit Where You Want It

Since the outdoor unit is another 300 pounds, you’ll want a high quality dolly and some ratcheting straps, as well as a strong friend nearby to help you wrangle it into place. Your goal is to put this thing somewhere beside your house that is out of the way, but also close to wherever you just put the air handler in the basement. Then you need a lineset that is long enough to connect them together – and shorter is generally better for both cost and performance reasons (we used a 35 footer).

We put our condenser on a couple of sturdy, level concrete pads.

Step Five: Run the Lineset

The lineset is a pair of flexible copper tubes that are wrapped in insulation. They are bulky, so even our 35-foot set came in a BIG roll the size of a big-screen television box. You need to carefully unroll and straighten it, and feed it in through a roughly 4” hole you drill in the side of your house so you can connect the condenser outside to the air handler unit inside.

We had the added challenge of having to punch through an eight-inch-thick BRICK WALL, so I had to spend some good workout time wrestling with this massive concrete core driller, mounted to a high-torque low speed drill.

Once the lineset is in position, the connection is refreshingly easy: you carefully follow the instructions to tighten on the right nuts with a wrench, open some valves with an alan key, and you will hear the refreshing PSSSSssssssshhhhh as the refrigerant is released into the system. (This is the part that an HVAC technician would normally have to do, Mr. Cool gets around the issue by using special valves and having pre-charged linesets. More expensive, but very much worth it for the time and labor savings!)

Final Step: Run the Electrical Wires

This will vary depending on the system, but ours called for the following wiring, which I subcontracted out to my partner Mr. 1500:

- A 40 amp / 240 volt circuit to the outdoor unit (which simply means running a length of 8 gauge wire and adding a 40 amp breaker to the box).

- A 20 amp / 240 volt circuit to the main unit

- Standard six conductor thermostat wire between indoor and outdoor units

- And finally, a run of the same thermostat wire between the indoor unit and your thermostat. We took the opportunity to upgrade to the super-lovely , which I now use (and love) in all my projects.

The Victory Lap: Fire It Up!

We cranked through all of these steps carefully and then flipped on the breakers with great fanfare: SUCCESS! – The lit up and started guiding us through its setup screens. Once complete, we slid the desired temperature way down in hopes of experiencing some much-needed Air Conditioning on this hot July day.

And nothing happened. We ran out to the outdoor unit and found it was just sitting there, with LEDs illuminated but nothing else happening.

We both started sweating bullets. Had we made a foolish mistake and bought a faulty unit? Did we screw something up in the install?

Nope – it turns out there is simply a three-minute delay between that first activation and the time Mr. Cool starts his cooling. Very slowly and with great grace, the big fan blades began to rotate, graaaaadually speeding up, with the hum of the compressor so quiet in the background that I had to press my ear up to the thing just to verify that it was really working.

But boy was it ever working – we ran inside and found that that icy cold air was just blasting out of each of the seven large vents spread throughout our building, and baking hot air was now shooting out of the outdoor unit. We had instantly beat the summer heat and everybody inside raised a cheer to this new luxury.

Epilogue, Three Months Later: How Well Does It Work?

Throughout the rest of the summer, we have had a lot of fun putting this system through its paces, and it has proven itself to be an incredible cooling machine. We had several events with over fifty hot bodies packed in for some of our entrepreneurship and social gatherings while outdoor temperatures were in the 90s – and we were able to maintain comfort effortlessly.

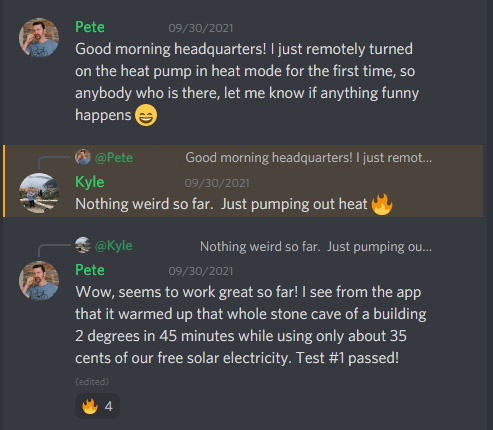

The next test will of course be the winter. Here in early October, we have just turned the corner where the building has required just a bit of heat to start some mornings. With a few taps on the Ecobee phone app, I was able to flip the system over to heating mode and give it a whirl. It worked great – heating the building quickly and quietly.

But I’ll update this article over time as we move through cooler seasons. I expect it to continue to perform just great – but it will be fun to verify and reassuring to skeptics out there once we see it with our own eyes.

Extra Cool Detail: How Much Electricity Does It Use?

Of course, being MMM I was not content to just sit back and soak in the cool breeze of accomplishment just yet. I needed one final bit of data – a record of just how much energy this heat pump was sucking down in both heating and cooling modes, so we can get a better estimate of how much money it is saving us over the years.

So I installed a system called the into the circuit panel, which is currently the best value on the market for such a well-designed gadget. This allows me to track and record the full details of the energy flow – through every circuit in the house if I choose to do so. For now, I just have it watching over the heat pump.

What I found is that in cooling mode, the Mr. Cool uses about 2600 watts on an ongoing basis (about the same as two large window air conditioners), which translates to 26 cents per hour of electricity. On the hottest days with the most people, I found the system ran about six hours, meaning our peak electricity use was only about $1.50 per day!

To me, this was pretty remarkable – this was a 95 degree day with 50 people in the building, roughly equivalent to trying to cool a mid-sized restaurant in Texas. Yet even if we repeated this extreme situation every day, we’d rack up an air conditioning bill of only about $45.00 per month!

I found that the heating mode was a bit more thirsty, with consumption at 4000 watts, or 40 cents per hour. Based on my earlier estimates of heat loss on the coldest possible days, we could be in for about 18 hours of runtime per day, which would be $7.20 of electricity. So, if the Headquarters were moved to an extremely cold climate and plunged into neverending 0F / -18C conditions for an entire month (which would make it colder than Duluth Minnesota or Ottawa Canada), we’d still face a heating bill no higher than $210 for the month. But in more realistic conditions for Colorado, we would expect about half of that level of energy consumption. And of course this is only for the month or two of our short cold season. For the rest of the year, heating is even easier.

Conclusion: Heat Pumps Are The Bomb

So there you have it: we dreamed about it for years, finally did it, and I could not be happier. It is such a joy to not even have an account with the gas company, and to know that this part of our expenses will be zero, forever.

And of course it’s even better to know that even the electricity cost numbers in this article are just for your own comparison – in reality, we make more than enough solar electricity run this whole thing for free just from the pretty squares of black glass on the roof. Free heating and cooling for life, with no pollution (with free operation of our laptop computers and beer fridges, and free charging of our electric cars to boot) – This truly is the way of the future!

In The Comments: Do you have any questions about heat pumps or other home efficiency products? And if you have a heat pump of your own, what do you think of it?